Variable frequency speed regulating elevator

Product Detail

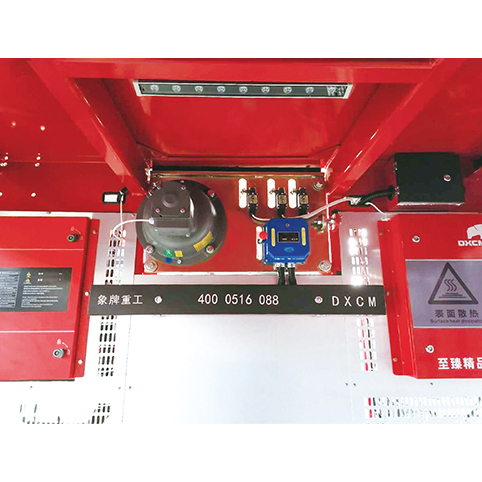

Variable frequency speed regulating elevators also include a number of safety equipment, such as emergency stop buttons and sensors that detect obstructions or malfunctions in the system. These elevators are commonly used in high-rise buildings and other structures. The variable frequency speed regulating elevator is a type of elevator system that uses an electronic variable frequency drive (VFD) to control the speed and movement of the elevator.

Traditionally, elevators have used a motor with fixed speed which had a mechanical system of gears and brakes to control the movement of the elevator cabin. However, with the development of VFD technology, elevators can operated with a motor that had variable speed, allowing for smoother and more efficient movement.

The VFD is connected to the elevator motor which adjusts the frequency and voltage of the electrical power supplied to the motor. By varying frequency and voltage, the VFD can control the speed and torque of the motor, allowing it to accelerate and decelerate smoothly and efficiently.

Advantage

- Energy saving, starting current less than rated current.

- The speed is adjustable, and the maximum lifting speed is 96m/min.

- Variable frequency control system.

- Stable starting and braking, low mechanical wear.

Technical parameters of frequency conversion speed regulating elevator

| Model Range | Model | Capacity (kg) | Lifting Speed (m/min) | Motor Power (kW) | Invorter Power (kW) | Counter Weight (kg) | |

| Single cage without counterweight |

SC100G | SC100BD | 1000 | 0-40 | 2×11 | 37 | 0 |

| SC100BZ | 1000 | 0-63 | 3×15 | 55 | 0 | ||

| SC100GS | 1000 | 0-69 | 3×22 | 75 | 0 | ||

| SC120G | SC120B | 1200 | 0-40 | 2×11 | 37 | 0 | |

| SC120BZ | 1200 | 0-63 | 3×15 | 55 | 0 | ||

| SC120GS | 1200 | 0-69 | 3×22 | 90 | 0 | ||

| SC200G | SC200BD | 2000 | 0-40 | 3×11 | 37 | 0 | |

| SC200BD | 2000 | 0-40 | 2×13 | 37 | 0 | ||

| SC200BZ | 2000 | 0-63 | 3×18.5 | 75 | 0 | ||

| SC200GS | 2000 | 0-96 | 3×26 | 90 | 0 | ||

| SC270G | SC270BD | 2700 | 0-40 | 3×18.5 | 75 | 0 | |

| SC270BZ | 2700 | 0-63 | 3×18.5 | 75 | 0 | ||

| SC270GS | 2700 | 0-96 | 3×27 | 90 | 0 | ||

| SC270GSN | 2700 | 0-96 | 3×27 | 90 | 0 | ||

| Twin cage without counterweight |

SC100/100G | SC100/100GD | 2×1000 | 0-40 | 2×2×11 | 2×37 | 0 |

| SC100/100GZ | 2×1000 | 0-63 | 2×3×15 | 2×55 | 0 | ||

| SC100/100GS | 2×1000 | 0-96 | 2×3×22 | 2×75 | 0 | ||

| SC120/120G | SC120/120GD | 2×1000 | 0-40 | 2×2×11 | 2×37 | 0 | |

| SC120/120GZ | 2×1000 | 0-63 | 2×3×15 | 2×55 | 0 | ||

| SC120/120GS | 2×1000 | 0-96 | 2×3×22 | 2×75 | 0 | ||

| SC200/200G | SC200/200BD | 2×2000 | 0-33 | 2×2×11 | 2×37 | 0 | |

| SC200/200BD | 2×2000 | 0-38 | 2×2×13 | 2×37 | 0 | ||

| SC200/200BD | 2×2000 | 0-45 | 2×2×15 | 2×37 | 0 | ||

| SC200/200 | 2×2000 | 0-60 | 2×2×22 | 2×55 | 0 | ||

| SC200/200BZ | 2×2000 | 0-63 | 2×3×18.5 | 2×75 | 0 | ||

| SC200/200BG | 2×2000 | 0-96 | 2×3×26 | 2×90 | 0 | ||

| SC200/200BGS | 2×2000 | 0-120 | 2×3×30 | 2×110 | 0 | ||

| SC270/270 | SC270/270BD | 2×2700 | 0-45 | 2×3×15 | 2×55 | 0 | |

| SC270/270BD | 2×2700 | 0-63 | 2×3×22 | 2×90 | 0 | ||

| SC270/270BD | 2×2700 | 0-96 | 2×3×33 | 2×110 | 0 | ||

| SC320/320 | SC320/320BD | 2×3200 | 0-45 | 2×3×18.5 | 2×75 | 0 | |

| SC320/320BZ | 2×3200 | 0-63 | 2×3×26 | 2×90 | 0 |

Remark:

- Recommended cage dimension (L x W x H) (m): 2.4x1.3x2.4; 3x1.3x2.4; 3.2x1.5x2.4; 3.6x1.5x2.4; 3.8x1.5×2.4; 4x1.5x2.4; 4.2x1.5x2.4 Cage dimension is according to requirement of customer requirements.

- The model code with "Gs" means "SEW motor set" provide.

- The model code with “N" means "Special New Function" provide.

- Recommended frequency conversion lift installation height≤ 500 meters.

*The above data is for reference only. CONTACT US for detailed information and customized solutions.

[gtranslate]

[gtranslate]